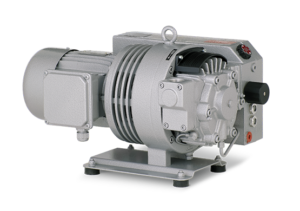

What is a Lubricated Vane Pump?

An oil-lubricated vane pump is a type of vacuum pump we offer at Callum & Brown. Pressure increase by volume reduction is the principle behind rotary vane operation. Inside the cylinder, the rotor is positioned eccentrically so that it’s almost touching the top of the cylinder. Rotor vanes are positioned inside the slots, so when the rotator starts turning, the centrifugal force causes the blades to be thrown out and slide against the internal surface of the cylinder. This creates a cell to be formed between two blades with a volume that changes constantly during the rotation of the blades. Air enters from the inlet port into a cell until the rear blade reaches the far end of the inlet port. At this point, the cell has reached its maximum air volume, after this point, the cell becomes smaller, decreasing its volume. This causes compressed air and increased pressure within the chamber. This continues until the cell exceeds and is then exited through the outlet port.

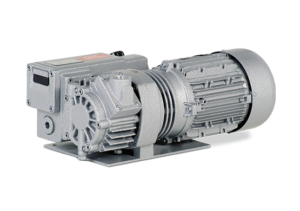

Why Choose a Lubricated Vane Pump?

This vacuum pump runs at a higher efficiency rate than the dry vane due to oil sealing. This pump also holds the potential for larger capacity pumps (up to 50 hp) and with higher amounts of water vapor, there are lower pump operating temperatures. This means lower discharge temperatures, which is better for your workplace atmosphere. The lubricated vane pump can tolerate higher levels of exhaust backpressure, making the efficiency run smoother.

What to Expect With This Technology:

The lubricated vane pump is more efficient than the dry vane because of the oil sealing, but this also means that there is a slight disadvantage. Due to the lubrication, this technology needs to be run above 15”HgV. Larger capacity pumps and higher amounts of water vapor are possible. The lubricated vane pump can also tolerate higher levels of exhaust backpressure.

Where Can You Use the Lubricated Vane Vacuum?

It depends on the application and process gases present, but the lubricated vane pump is used in a wide array of industrial, medical, and laboratory applications. It allows for much deeper vacuum levels than most technologies and is perfect for environmental, pneumatic conveying, woodworking, laser cutting, thermoforming, food & beverage packaging, and industrial applications.

Cullum & Brown is here to guide you through every buying process. We look at the entire application and system to provide the best possible technology for our customer’s needs. Contact us today to learn more.