What You Should Consider

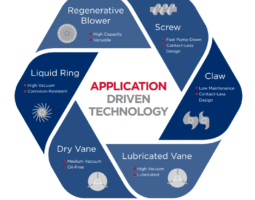

When choosing between vacuum pump technologies, there are several key factors to consider. The specific application, required level of vacuum & capacity, ROI, and maintenance concerns are just a few factors that influence what technology is the best choice for your industry.

Reference this guide for a first look into the different types of vacuum pumps offered by Cullum & Brown, but for a more detailed look into our inventory, contact one of our expert technicians!

What is your industry?

Choosing the proper vacuum pump technology is essential to ensuring application success, and less unnecessary downtime while extending the life of the vacuum pump. Whether you’re in the medical field, food processing industry, woodworking, or chemical processing there are different factors to consider when choosing the correct technology.

Starting off knowing which vacuum pump technology is right for your industry ensures that there will be lower maintenance costs and upkeep, this can also extend the overall life of your vacuum pump.

Certain industries also prefer when the technology used is more energy efficient. Energy consumption can be a huge draw while executing particular applications, so it’s important to think about how much energy your company uses on a daily basis. While some vacuum pumps are more efficient than others, most models can be used with a VFD for increased flexibility and efficiency.

What is the job that needs to be done?

The vacuum pump recommended by our trained experts depends almost entirely upon the application and customers’ specific needs. While many different styles of vacuum pumps may work for a specific application, certain technologies may be better suited.

You should consider the level of pressure and capacity required, as well as what gas is in the process when considering which technology to choose. These factors differ drastically from application to application.

What are the roadblocks you’ve experienced in the past?

One of the first things our team of experts asks is what problems might have arisen from past vacuum pump technologies that were used. We want to know if your last vacuum pump performed to your standards and did you have any issues?

More often than not, our customers are looking to replace a technology that has run its course. Once a piece of equipment has reached the end of its lifespan, you’ll need to get it replaced as soon as possible. Poor efficiency and increased downtime/maintenance cost are functions of vacuum pumps that may be near their end of life cycles, which usually have a negative monetary impact on your organization.

If your vacuum pumps aren’t performing properly (or you are not utilizing the proper technology), you run the risk of decreased output or potential halts in operations altogether.

What can be improved?

- What is something you would like to change?

- What are your goals for the longevity of your technology?

A common goal that is often discussed when changing technology is always the return on investment. The right technology will lower maintenance costs and provide long term solutions for your production needs. Energy efficiency is also a contributing factor when it comes to selecting the correct vacuum pump technology for your business.

What can Cullum & Brown do to help you reach these performance goals? We have the technology and products needed with the trained experts to handle all of your questions when it comes to choosing the right vacuum pump technology.

Cullum & Brown is here to guide you through every buying process. We look at the entire application and system to provide the best possible technology for our customer’s needs. Contact us to learn more.