Staying ahead of the curve is not just a necessity, but a driving force for success. Custom Truck One Source, a renowned name in the industry, understands this well and has recently embarked on an ambitious project to build a 235,000 sq. ft. production facility. To bring their vision to life, they turned to the experts at Cullum & Brown for innovative solutions, specifically in designing and implementing a compressed air system for the facility. The result? A custom-tailored compressed air solution that seamlessly integrates old and new components, setting the stage for a new era of productivity.

A Strategic Partnership for Success

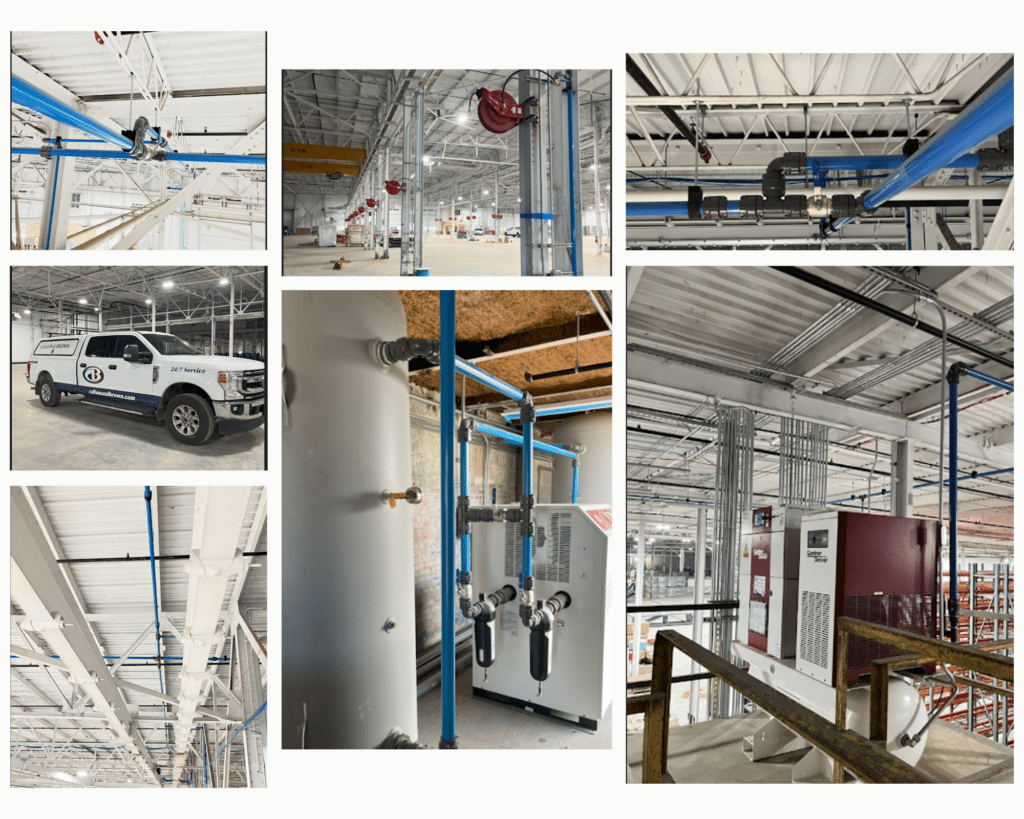

Custom Truck One Source’s decision to collaborate with Cullum & Brown for their compressed air needs is a testament to their commitment to excellence. The project entailed the integration of existing used compressors with new compressors and dryers that Custom Truck One Source had recently acquired. This presented a unique challenge, which Cullum & Brown was more than ready to tackle.

Integrating the Old with the New

Cullum & Brown’s approach was as innovative as it was practical. They integrated two of Custom Truck One Source’s existing compressors with a new compressor, new dryer, and a new compressor air station tank and dryer combo, all strategically located in a remote area of the plant. This meticulous planning ensured that the old equipment could harmoniously coexist with the new, achieving optimal efficiency.

A Seamless Installation Process

The installation process is often where the real magic happens. The Cullum & Brown installation team worked seamlessly with all production departments, ensuring that air was efficiently delivered to every corner of the facility. This meant installing nearly 4,000 linear feet of air pipe and mounting over 85 drops with hose reels. Dozens of additional drops to production equipment were strategically placed, tailored to Custom Truck One Source’s specific needs.

Adapting for the Future

A key feature of Cullum & Brown’s solution was the forward-thinking approach to system design. The air pipe header was installed with valving to allow for the isolation of different production zones. This forward-looking design caters to potential future expansions, ensuring that they can seamlessly integrate new equipment without disrupting ongoing production.

This collaboration between Custom Truck One Source and Cullum & Brown to create a cutting-edge compressed air system for the new production facility is a remarkable example of what can be achieved through innovation, collaboration, and trust. Cullum & Brown’s ability to seamlessly integrate old and new components, coupled with their forward-thinking system design, is a testament to their commitment to excellence.

If you are interested in Cullum & Brown’s installation process and methodology for compressed air system design, feel free to contact us by submitting a quote or giving us a call today.