Quick, Efficient Leak Detection with SONOTEC’s SONAPHONE

When your compressed air system has a leak, your company’s equipment and profits suffer. Even minor leaks can cause unnecessary wear and tear on your system and decrease its efficiency.

Cullum & Brown’s years of service prove we are versed in using new tools that help keep your equipment in peak condition. And our most recent equipment purchase continues this trend.

Digital leak detection

Cullum & Brown recently acquired SONOTEC’s SONAPHONE, a digital leak detection solution. Let’s break down how this equipment will improve your company’s operation and explain why we’re proud to add it to our digital toolbox.

Accurate detection

Lost energy impacts efficiency and savings

Did you know that the average energy loss due to compressed air system leakage is around 30%?

Common leaks (like those on couplings and valves) make compressors compensate for a system’s permanent pressure loss. And although your equipment continues to provide compressed air, your operating costs increase, and energy efficiency decreases.

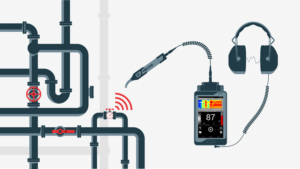

SONOTEC’s SONAPHONE uses ultrasound testing technology to help locate the exact location of a leak. Once a leak is detected, the tool uses broadband analysis methods to help classify and assess the loss caused by the leak.

SONOTEC’s technology also is effective in loud, industrial environments. The SONAPHONE broadband testing device will record ultrasound signals up to 100 kHz. All recorded information is displayed in spectrogram form, making it easy to distinguish leaks from interferences.

In addition to reading information on SONAPHONE’s visual display, users can listen to and locate leaks with headphones using a transformed audible signal.

“Whereas only one sound can be heard with standard ultrasound testing devices, broadband ultrasound testing technology opens up an entire symphony of flows and airborne sound.” – Prof. Dr. Peter Holstein (Strategic Development, SONOTEC GmbH)

Effective evaluation

Once SONAPHONE identifies and isolates an ultrasound source, its precise locator finds and records the maximum sound level of the leak at a distance of 5 cm. The leak is then evaluated (l/min) and classified (1-5) using the LeakExpert app.

LeakExpert’s user-friendly interface guides technicians through the leak testing process. The easy-to-use app ensures leaks are classified by size, making it easy to prioritize future maintenance.

Clear documentation

After evaluating found leaks, no one wants to spend unnecessary time filing and reporting findings. Thankfully, SONAPHONE allows a user to create quick reports that simplify a project’s follow-up measures. Users can provide detailed leak documentation (written and photographic) and prioritize repair work in one click.

And rest assured knowing that LeakExpert’s report meets the documentation requirements of DIN EN ISO 50001. The app also provides reliable information regarding the individual and total leakage lost in the compressed air system.

–

Are you interested in finding out more about how Cullum & Brown uses SONOTEC’s technology to improve your workflow? We’re here to answer all your questions. Contact us today to learn more about how digital leak protection can help your business!