Vibration Analysis

Reduce unplanned downtime and risks

Increase uptime and avoid unplanned downtime by partnering with us to utilize vibration analysis on all of your major production equipment.

When your components, machines, and structures are in use, they create standard and repeatable vibrations. Vibration analysis collects that vibration data into a software program, allowing our experts to thoroughly analyze it and determine the overall condition of your mission-critical equipment.

Adding vibration analysis to your current maintenance or predictive maintenance program (PDM) allows your team to fix common equipment problems as they arise, which leads to many benefits:

- Reduced unplanned downtime and risks

- Reduced maintenance costs

- Enhanced reliability

- Extended asset life

- Increased production output

How Vibration Analysis Works

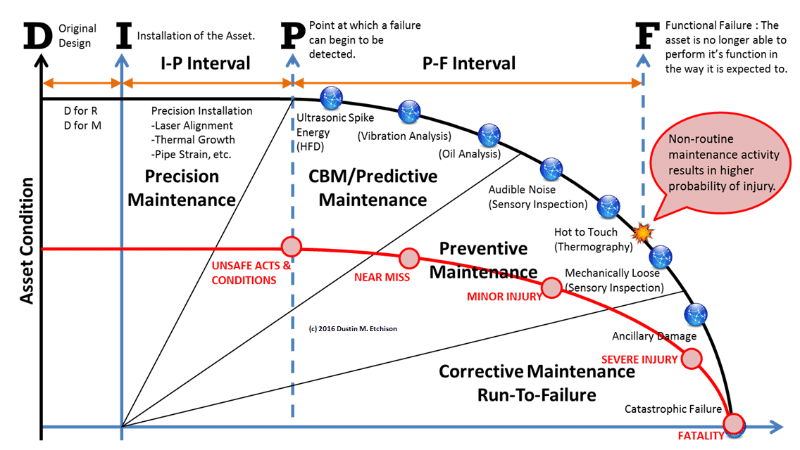

Vibration analysis is a critical component of predictive maintenance, enabling the early detection of equipment issues before they escalate into costly failures. At Cullum & Brown, we leverage advanced Emerson CSI 2140 technology to perform comprehensive vibration analysis on your major production equipment, ensuring optimal performance and reliability.

Our Vibration Analysis Services Include:

State-of-the-art data collection technology

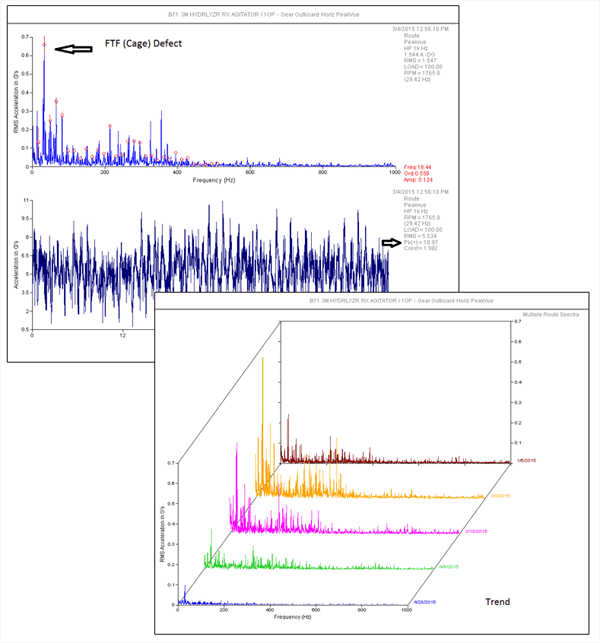

Cullum & Brown utilizes the latest Emerson CSI 2140 technology to collect data in three axes: horizontal, vertical, and axial at each bearing location in the equipment train. These reports, which use Emerson’s proprietary Peakvue technology, help us identify early bearing defects as they develop and accurately determine the severity of faults. The more detailed information we can enter into the database, the more likely we can pinpoint problems to the exact defective component(s).

To develop accurate and reliable trend data, we recommend testing and collecting data monthly or quarterly to start. Depending on the history and level of preventative maintenance performed, we may recommend lengthening the collection periods to give us the best roadmap to equipment success.

Expert Data Analysis

Utilizing Emerson’s AMS Machinery Manager software, we compile all the vibration data into a unique report for each customer. These reports can be customized to provide the specific level of data needed by your team. We aim to provide the most accurate and reliable information and analysis in a way that supports your business goals.

Customized Reporting

We provide tailored reports that include equipment identification, severity assessments, analysis summaries, recommended corrective actions, and supporting trend, spectrum, and waveform plots.

Collaborative Consultation

Our vibration analysts will review the report with you in detail, addressing any questions and collaboratively developing a plan to resolve identified issues before they lead to catastrophic failures.

Benefits of Implementing Vibration Analysis

- Reduced Unplanned Downtime: By detecting potential issues early, we help prevent unexpected equipment failures, ensuring continuous production and operational efficiency.

- Lower Maintenance Costs: Early identification of problems allows for planned maintenance activities, reducing the need for costly emergency repairs and extending the lifespan of your assets.

- Enhanced Production Output: Maintaining equipment in optimal condition leads to increased productivity and improved product quality, contributing to your bottom line.

With over 135 years of experience, Cullum & Brown is dedicated to keeping manufacturers operational through comprehensive services, including vibration analysis. Our team of experts is committed to partnering with you to enhance equipment reliability and performance.

For more information or to schedule a vibration analysis consultation, please contact us at:

Kansas City Office: 1200 Burlington North Kansas City, MO 64116 Phone: 816-842-7711

Springfield Office: 2143 West Vista St. Springfield, MO 65807 Phone: 417-869-0066

Invest in proactive maintenance with Cullum & Brown to safeguard your operations and achieve long-term success.

Let's Talk Solutions

From turnkey equipment and system installs to 24/7 emergency service, we can help.

Contact Us