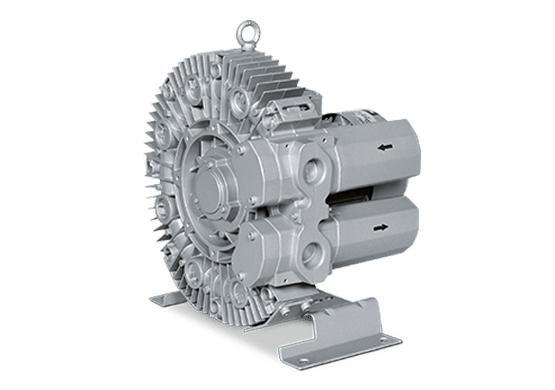

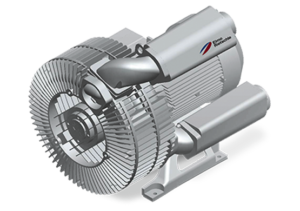

What is the Regenerative Blower Process?

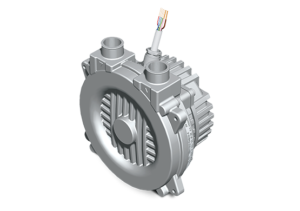

The regenerative blower can be used as either a vacuum or a positive pressure machine. Gas is sucked in through the inlet, and with every rotation of the gas kinetic energy is added. This results in a further increase of pressure along the side channel. Centrifugal force is the impeller blades accelerate the gas outward into the channels and the pressure increases. The side channel then narrows at the rotator, sweeping the gas off the impeller blades and discharging it through the outlet silencer.

Learn More

Benefits of the Regenerative Blower

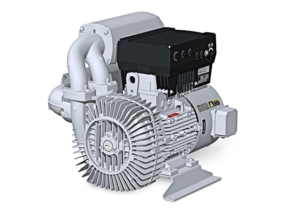

With this technology, it makes the vacuum keep noise levels low while in use. It is also pulsation-free, and virtually unaffected by dust and small particles, making it maintenance-free. It also has an adjustable speed via external or integrated variable frequency drives and holds differential pressures up to 434 in. H2O. Regenerative technology is the lowest upfront cost and the lowest associated maintenance cost.

What to Expect with Regenerative Technology

This technology is typically one of the lowest upfront costing vacuum pumps and is also one of the lowest associated maintenance costs. The one drawback is a relatively low differential pressure when it comes to efficiency. Overall, regenerative technology is good for a wide variety of applications.

Where Can This Technology Be Used?

This depends on the application and process gases present. The Regenerative Blower Pump is great for environmental applications, packaging, dental, plastics, woodworking, laboratory applications, automotive, printing, soil remediation, wastewater treatment, and landfill degassing. Overall, the Regenerative Blower Pump is the perfect low cost and low maintenance technology for your work.

Cullum & Brown is here to guide you through every buying process. We look at the entire application and system to provide the best possible technology for our customer’s needs.