If you have experience working in an industrial setting, you understand the importance of blowers for production. During the hot summer months, there is an increased risk of blower failures, which can disrupt operations. This post will examine two main types of blowers—positive displacement and centrifugal—and dive into their applications, benefits, and key differences. As a trusted source in the Midwest, Cullum & Brown not only distributes these blowers but also provides expert servicing. The company ensures that your operations run smoothly year-round, even under the most challenging conditions.

What is a Positive Displacement Blower?

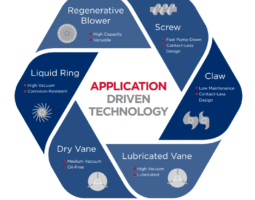

A positive displacement blower, also known as a PD blower, operates by trapping a fixed volume of air and then discharging or forcing it out against the system pressure. These blowers are integral to a wide array of industries due to their ability to handle diverse applications. The most common types found in these settings are rotary lobe and screw blowers, which are chosen for their efficiency and reliability in continuous operations.

Advantages of Positive Displacement Blowers

The main advantage of positive displacement blowers is their ability to maintain consistent airflow even when discharge pressures vary. This makes them essential for applications that require stable and continuous air delivery. Their strong performance across a wide range of pressure and flow settings makes them indispensable for precise air control in critical processing and handling operations.

What is a Centrifugal Blower?

Centrifugal blowers utilize high-speed impellers or blades to give air or other gases velocity before discharging them against the casing. They are suitable for applications that require large volumes of air at relatively low pressures, such as in HVAC systems and various drying processes.

Advantages of Centrifugal Blowers

These blowers are highly effective in environments where a large volume of air needs to be moved. They can operate at varying speeds with minimal maintenance, making them suitable for ventilation, air conditioning, and in settings where air quality control is essential.

Key Differences Between Positive Displacement and Centrifugal Blowers

The primary distinction between these two types of blowers lies in their operational mechanism. Positive displacement blowers deliver air at a constant rate regardless of pressure, whereas centrifugal blowers provide a steady pressure at varying flow rates. Additionally, the maintenance and energy efficiency between the two can differ significantly, making the choice dependent on specific industrial needs.

Additional Considerations

Understanding the difference between blowers and compressors is also crucial, as the latter increases the pressure of the gas by reducing its volume. Comparing blowers to pumps, it’s important to note that while both increase the pressure of the fluid, pumps are typically used for liquids, not gasses.

Choosing the Right Blower

Selecting the right blower involves considering factors like volume flow rate, pressure requirements, and environmental conditions. For high-pressure applications, a positive displacement blower might be ideal, whereas centrifugal blowers may be better suited for applications requiring large volumes of air at lower pressures.

The Bottom Line

Whether you choose a positive displacement blower or a centrifugal blower depends on your specific needs and the demands of your industry. Both offer unique advantages and can provide significant benefits in the right context.

If you need further assistance in selecting the right blower for your application or have any other questions, contact our team for more expert advice.